So you need to spec some equipment, or maybe some décor items. As if you don’t have enough choices among the thousands of suppliers of off-the-shelf pieces out there, there’s a whole other universe of custom fabrication.

You can get custom-spec stainless fabrication, or custom millwork for wood or other materials. There are dealers who do their own fab, though not many. Most subcontract it to outside fabbers. Fabbers themselves generally specialize in either steel or wood/other millwork, and a few here and there do both steel fabrication and millwork. Then there’s another group—OEM manufacturers who produce their catalog items plus do fab and maybe millwork too. The possibilities are virtually endless, and even old hands at specifying custom fab are discovering new alternatives popping up all the time.

So how do you even begin to sort your options?

To Customize, Or Not To Customize

First question is, “What are you trying to do?” Fortunately suppliers can help you through the analysis. Are you better off with standard catalog items, or will custom be worth it? The big question is, as it is with most business decisions, whether your capital budget is strong enough to go for continuing paybacks.

Are you outfitting a prototype? If you’re going to repeat installations, unit costs can come down, and you can work that into your decision-making. Or are you doing a one-off? If your footprint gives you flexibility, off-the-shelf might be your answer. If you have a really constricted space or other unique requirements, custom might make more sense.

As for that matter of budget: Custom fab often—though by no means always—costs more than off-the-shelf. Do you have the capital budget for a custom configuration that can save you space, utility or labor costs going forward? Every time wages or utility costs go up, payback goes up.

And here’s another angle to consider: If you’re comparing apples to apples—the price of a buyout prep table to the price of a custom prep table—you’ll get one set of numbers. However, if you’re customizing, you might consider custom fabbing one piece that in effect will replace multiple catalog pieces—in which case your math will look very different. And then there are other considerations you might not think of. Fab suppliers can examine those options and run the numbers with you to figure out where they can help and where they can’t.

“The first thing we do is try to understand what the brand is doing in its kitchen,” says Todd Slawson, Senior V.P. of Client Services for Columbus, Ohio-based N. Wasserstrom & Sons, which manufacturers stock items and does a lot of custom fab and millwork. “Will this be a prototype to be replicated? Once we understand, we look at the food products and general design. Then we educate the operator about the differences between a manufactured piece and what we would provide as a custom piece. How much and what shape space do they have? That all factors in.”

Frequently Customized

Slawson notes most commonly custom-fabbed kitchen pieces include production/make/assembly line type equipment such as prep tables, overshelves, drop-in pieces and so on. “Every operator brand, every concept has a little different spin on the operations and food product side. Because of that, prep, cooking and assembly all might lend themselves to unique configurations.”

Elsewhere in the facility, Slawson says dishroom needs might benefit from custom sizing or layout of load, scrap and unload surfaces. “In QSR, maybe the drive-thru area needs custom fitting. Prep sinks, prep tables, work areas—maybe you will have a standard 24-in. x 36-in. prep surface/work table, but could it benefit from two mid-shelves, or casters, or flanges?” Often custom features can make a big difference in functionality, especially given the trend to ever-smaller overall footprints.

Front-of-house can involve stainless fab, but more likely it’s millwork, or a combination of both. “Some areas, such as beverage counters, are more metal,” Slawson says. “Front-of-house seating is millwork. Condiment counters and queue lines generally are millwork finished with laminates, hardwoods, Corian, those kinds of materials.” Another common front-of-house custom piece is a salad bar.

Managing The Process—Early, Early

Managing the design process, no surprise, is a key focus. Like managing any design effort, getting all the players involved early is crucial. Accurate communication, from general operational goals and ROI to precise measurements of dimensions, will make the difference between smooth installations and nightmarish, unprofitable rework and delays.

“We are proponents of getting involved as early as possible in the design/spec process, especially for prototypes, so decisions can be made with everyone involved,” says Craig Anderson, Project Director/Senior Designer at Irvine, Calif., dealer TriMark Raygal, which does a lot of design-build and subcontracts fabricators. “We work closely with the operator, architect and construction team early on to be sure we are not pushed into a corner” either on the design process or the timeline.

Getting everyone in the loop from the start is especially important in the case of custom fab because some ideas look great on paper but won’t work in the physical world. “With computers today, it’s easy to draw anything,” Anderson says. “But it comes down to how practical that shape or size or configuration is for the person who actually has to build it. And that translates to cost. What is the look that the designer wants versus what is functional and operational?” Some things are not possible, and some things are possible, but at prohibitive cost and no practical payback.

At St. Louis-based Duke Mfg., which produces catalog items as well as custom fab, Senior Project Manager Dean Anderson agrees. “The whole process from the design stage to installation stage all hinges on communication and at which stage a project gets passed to the next team member for that project,” he says. “To start a project correctly, you need to be able to take the vision of a consultant or site director and be able to transfer that idea to a quote and drawing that shows them exactly what we believe that vision is.” As some projects have multiple phases and multiple managers, communication becomes just that much more important.

“We listen carefully to find out what the operator really needs,” says Jonathan Hood, V.P. Strategic Solutions, Franke Foodservice Solutions, Smyrna, Tenn., which manufacturers as well as does custom fab. “We help them create standards [in layout and custom fab] so as they go forward, they don’t have to reinvent the wheel.”

The idea is repeatability and efficiency. “When you think custom fabrication, you need to think standardization,” Hood continues. “You should go modular. As you create your concept, you must understand that although you want to build custom, you also will want to make changes in the future.” The more you can carry over from the original drawings—metal gage, bracing, other features and manufacturing details—the quicker and simpler any changes will be.

Many of Franke’s clients are putting big emphasis on small spaces, which puts a lot of pressure on conventional thinking. “A lot of catalog items go horizontal, and they require more steps around the kitchen,” he says. “A lot of facilities run electrical or refrigeration, water and gas and everything within the walls, and then it’s very hard to do changes later.

“We like to keep things modular. We design custom fab pieces for fewer steps and multiple uses. That often means we go more vertical, which optimizes smaller kitchens, smaller footprints,” he says.

Very often, the Franke team finds that the holistic, modular approach yields other harder-to-see benefits as well.

“We have a client that recently went through a redesign,” Hood says. “The new equipment package costs more. But we took out a drain and water line from the floor. We took $5,000 out of construction cost that you would not think of when thinking custom fab. We took construction dollars and moved them to equipment. The result was a more-nimble, more-quick facility. Sometimes catalog items just won’t do what you want.”

Figuring Lead Times

Another thing to keep an eye on is lead times. Lead times rise and fall seasonally, just as they do for standard manufactured items, all our sources indicated. Weather is a factor—first-quarter building and installation is pretty slow, especially in the northern tier. Fourth quarter is a rush to finish the year’s projected activity. In between is a ramp-up from spring through autumn, notably influenced by things like school renovations that have to be done during summer. If you know you’re going to need product delivered during busy periods, it’s best to arrange it in advance.

“For custom fab, once the drawing/review process is done, typical rule of thumb is six to eight weeks for lead times,” TriMark’s Anderson says. “That can be compressed, but it’s difficult. And of course it depends on the size and capability of the fabricator, the complexity of project, and the time of year.”

Other factors enter into lead times too. “One of the biggest misconceptions is that custom items can be made as quickly as a standard off-the-shelf item,” says Dave Martin, Application Designer & Engineer at Duke. “Custom needs to be laid out and engineered to specific needs, and that could, and does, add to lead times and sometimes costs.”

Mark Brenner, V.P. Sales at Eagle Group, Clayton, Del., which manufactures stock pieces and does its own fabrication and millwork, notes lead times even for a chain can vary from installation to installation. “Does the package differ from store to store? If stores are different, lead times can be longer because drawings are different. If the back-of-house is the same, that makes it easy, and you can do the fabrication for a store in a couple weeks.”

“Consistency definitely makes my job and everyone’s job easier,” adds Brian Powell, Engineering Manager at Eagle. And that translates to higher quality and quicker turnaround. Chain customers with repeatable drawings and relatively few points of contact often can expect quicker lead times. Other kinds of projects, especially if they have multiple contacts at multiple stages, introduce more complexity and can take longer.

Choosing Suppliers

So maybe after some thought you decide you need to look into custom fab. If you haven’t handled fab before, who do you talk with to get the ball rolling? No doubt you already have channel partners—a dealer, a consolidator, etc. Maybe you’re working with a consultant. Ask them whether they can help you design what you need and recommend a fabricator.

Talk to your peers in the industry. Ask them who they recommend, who they don’t, what were their experiences, etc. You need fab work that’s good quality and on time. Your peers will tell you what they know. They might steer you to a designer, a dealer or directly to a fabricator.

Think not only about the piece(s) to be fabricated, but how the whole workspace might be transformed. Ask your partners about logistics issues. “We will look at regional fabricators or mills to execute projects in some cases,” Anderson (at TriMark) says. “But at the end of the day, especially on the chain side, consistency is important. Someone who already knows your project can do it better, quicker, rather than training a new supplier just to reduce transportation costs.”

As for complexities, consider how many moving parts, so to speak, are in your project—how many pieces, and how many materials. Many fabricators tend to specialize in one material or another. Hoods and exhaust regulations are a sophisticated business, and dedicated hood manufacturers, with their testing capabilities and UL listed models, are a bigger part of the market. Fabricated hoods are a shrinking segment, with a small number of fabbers competing well.

Some sources do both metal and wood/other. (Other construction type materials such as ceramic tile, stone and composite often get subcontracted.) Is there an advantage in finding one that does both? Maybe. If you have complex pieces incorporating both steel and wood, for example, it might be handy to have a single shop producing both parts so you know they’ll fit before they ship.

Checklist For Custom Fab & Millwork

- You’re customizing to get a payback—in time, labor, space and/or construction costs. Think outside the box. Can you customize one piece that will replace two or more off-the-shelf items? Your suppliers can help you.

- Ask your peers at other companies what fab and millwork suppliers they would and would not recommend. They’ll tell you.

- Communication is everything. Get operators, architects, designers, fab/millwork contractors and construction teams together at the beginning of planning so everyone hears everything.

- The more complex a design is, the more challenging the fabrication is. Communicate and coordinate accordingly.

- Make sure the design can actually be produced cost-effectively. Some configurations just can’t be built efficiently.

- In an era of shrinking footprints, make use of vertical space.

- If you’ll want custom pieces installed during busy summer months, get them fabricated/milled early.

- If you have pieces that combine metal fab and millwork, consider a shop that does both and can assure fit before shipping.

As originally printed in FER Magazine fermag.com

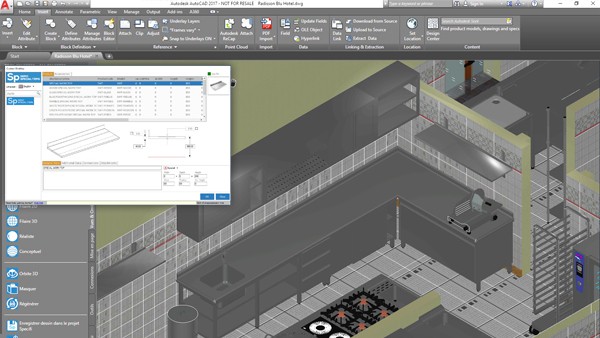

Specifi’s Design software, in conjunction with your CAD system, enables you to create customized items, including worktops and drop-ins, in just minutes rather than hours.

Watch this 2 minute video to see how we can help you save time and assure the accuracy of your commercial kitchen projects

The post Fab-Tastic Journey appeared first on Specifi®.